Welcome to First 90 Days, a series dedicated to examining how pharma executives and other leaders are planning for success in their new roles. Today, we’re speaking to Simone Steiner, Transgene’s new chief technology officer, about how the company is transitioning from early- to late-stage testing and advancing its manufacturing capabilities

Oncology vaccines are gaining traction in the clinic as potential game changing treatments for cancer. But manufacturing is still a difficult hurdle to overcome.

Simone Steiner recently joined France’s Transgene as chief technology officer to lead the complicated manufacturing process for the pharma’s individualized neoantigen therapeutic vaccines. Steiner, who calls herself a “typical Swiss,” came to Transgene after holding technical roles at biotech companies and spending more than 10 years at Novartis, where she contributed to large-scale production strategies and honed her manufacturing expertise.

She joined Transgene about six months after one of the company’s early-stage assets failed in the clinic. Trangene’s experimental cancer vaccine was found last year to have no effect on progression-free survival in solid tumors in a mid-stage trial as an add-on to another cancer drug, avelumab. The failure was “disappointing,” CEO and chairman Dr. Alessandro Riva said at the time, and the company’s share price plummeted almost to the penny-level in the aftermath.

“In drug development the risks are high, and for anyone who has been in the industry for a period of time, they are likely to have experienced such failures,” Steiner said. “This was before my time, but one of the things I thought was attractive about Transgene was the pragmatic approach to a … failure.”

That approach included narrowing the scope of its study, down from several cancer types to a subset of cervical cancer patients, and moving forward with another lead asset. The pivot exemplifies Steiner’s view of needing to be a “nimbler” biopharma company with the ability to make urgent decisions that are not possible in larger companies.

“Big Pharma is like a big tanker,” she said. “It takes a long time to turn and a long time to gain speed; once they have speed, they will continue efficiently along a path but are slow to adapt and change.”

Steiner has come aboard Transgene at a time of transition for the French biopharma, as it pushes on with its lead asset and furthers its manufacturing initiatives.

Cancer vaccine efficacy

Transgene is taking aim at early-stage cancers with virus-based therapies targeting neoantigens on tumors. The company’s myvac platform creates individualized immunotherapies that stimulate and “educate” a patient’s immune system to destroy cancer tumors.

“Unlike other approaches, it is tailor-made for each patient, based on the mutations specific to their tumor,” Steiner said. “We use AI to select the targets most likely to induce a strong immune response and incorporate these neoantigens into our viral vector.”

The platform’s first candidate, TG4050, completed patient screening for phase 2 testing last month in HPV-negative head and neck cancers. Transgene recently presented phase 1 findings at the annual American Society of Clinical Oncology conference in Chicago, revealing that patients who received the immunotherapy were disease free after more than two years in follow-up.

“What’s especially encouraging is that these responses … can last for over a year after treatment ends,” Steiner said of the results. “And in high-risk head and neck cancer patients, this may help prevent relapse, which is a major step forward.”

Manufacturing prowess

Currently, a political push to pressure American drugmakers to manufacture their products stateside has gained steam. But success there needs to be earned.

“While some countries have historically provided more attractive conditions for manufacturing, relocating these capacities is a slow and complex process, so it’s key to make the right decisions that support the long-term success of the business,” Steiner said.

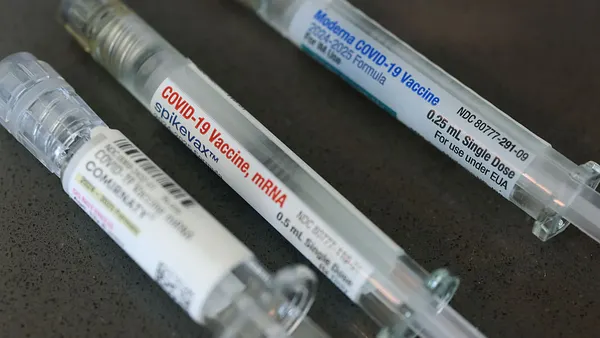

Transgene’s manufacturing process is complex, though “less complex than cell therapies,” said Steiner. In her role, she’s evaluating how to optimize and automate the process with quality control.

“Since we produce far more batches than for traditional medicines, we generate a large volume of data that can be analyzed using machine learning expertise,” she said. “This enables us to monitor production in real time. Instead of performing full lab tests on every single batch, we’re working toward a model where we can release a batch based on validated in-process data — only running additional tests when something unusual is flagged.”

Individualized medicines like Transgene’s face high costs and a complex supply chain, but automation is easing these challenges. Plus, “the pioneering work in autologous cell therapy” has helped pave the way for supply chain solutions, Steiner said.

What’s on Steiner’s to-do list for the rest of 2025? Moving ahead to complete the phase 2 trial of TG4050 and drawing up commercial strategies.

“At the same time, we are preparing for the next steps toward a pivotal trial,” Steiner said. “Transitioning from early- to late-phase development in individualized medicine also puts us into launch preparation mode, so we are formulating plans for a large process simplification program as part of a pre-commercial launch activity.”