Disruptive Innovation: Growing Vaccines in Plants

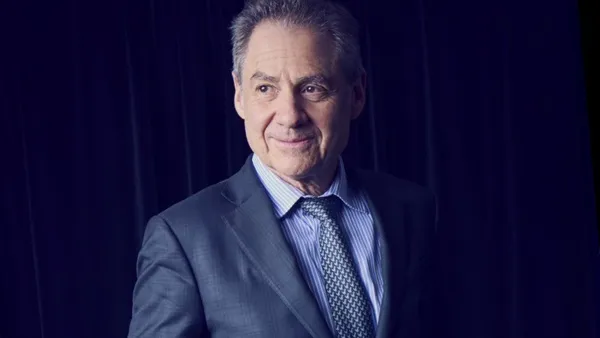

Sidebars: How Plant Technology Works About Medicago Expert Frederic Ors, VP of business development at Medicago, discusses the company’s market-changing technology for developing vaccines. Last Word PV: Your technology uses plants instead of eggs to grow vaccine antigens. How does the technology work? Ors: Vaccines today are made using eggs. Manufacturers infect the eggs with the virus and then extract the virus from the egg to make the vaccine. We have developed a new way of producing vaccines that does not rely on the viruses at all. All we need is the genetic code from the main protein of the virus. With that code, we synthesize the corresponding DNA sequence and then we insert it in a vector using a bacteria that has the ability to transfer a piece of DNA into cells. We use the plant Nicotiana benthamiana, which is in the same family as tobacco. Each cell of the leaf receives the target DNA. This takes only two minutes and then we put the plant back in an incubation room for five to 10 days, depending on the strains. During that time, the cell machinery of the plant cells take care of the DNA sequence and create a virus-like particle. PV: Why use plants instead of eggs to create vaccines? Ors: There are several advantages of plant-based technology. One is the speed at which we can produce the vaccine antigens. We can produce a new strain in less than a month. When H1N1 appeared in 2009, we were the first company to produce a vaccine and we did that in 19 days. For the egg-based and the cell-based technologies, manufacturers need three to six months to deliver vaccines. Another big advantage is that we can get more product than eggs can produce. For example, one plant will give us more than 100 doses of a vaccine, while each egg may provide enough for three or four doses. Another advantage is immune response. Our process creates a synthetic version of the virus. The body recognizes this as it would a live virus, and we can get an immune response that is far closer to that of an infection. With egg-based production, companies have to destroy the virus and cut it in small pieces, and that affects the immune response. The level of protection with egg-based production is actually quite low; it can be about 50%. The industry has been using the current process for 50 years. The current egg-based process works, but there is a debate to its efficiency. More and more people are saying it works, but it’s not very good. Some companies have started to use cell cultures for vaccines. That’s not a huge departure for companies since they are using cell cultures for antibodies and other proteins. PV: Are there any concerns with using plants in the tobacco family? Ors: There is no trace of nicotine from the plant because we are extracting a particle from the plant to produce the vaccine. The process of purification eliminates any traces of any potential contaminants that may come from the tobacco. PV: What is the status of your research? Ors: We’ve done four clinical trials, two in the United States and two in Canada. We’ve done one Phase II trial and we’ll be completing another one soon. Our influenza vaccine is the first product in the pipeline. The results of a Phase I study for the influenza vaccine were released in April. That trial for an H5N1 Avian Influenza VLP vaccine showed positive results and was safe and well-tolerated. PV: What challenges do you face in developing a new technology? Ors: One of the challenges of a new technology is getting first approval; the regulatory authorities don’t have experience with the technology. We have to work with regulatory authorities to help them understand the technology and to help them create regulation for these newer products. There is one product that has been approved using plant cells to produce an enzyme. Elelyso, which is manufactured by Protalix Biotherapeutics, a recombinant protein enzyme approved in 2012 for enzyme replacement for Gaucher’s disease. This is the first approval for a product that was obtained through plant-based technology. How Plant Technology Works 1. Synthesis. Gene synthesized from sequence of pandemic virus. 2. Vacuum Infiltration. Genetic material introduced into plants through vacuum infiltration. 3. Incubation. Plants are incubated for up to six days in greenhouses for protein expression and VLP formation. 4. Harvest. Plants are harvested to extract VLPs. 5. Purification. VLPs are purified to obtain clinical grade material. Source: Medicago. For more information, visit medicago.com. About Medicago Medicago is focused on developing vaccines based on proprietary manufacturing technologies, which produce recombinant vaccine antigens in plants. Compared with traditional egg-based and cell production systems, plants are uniquely capable of efficient protein expression at very high yields. The company’s technologies include: Proficia, virus-like particles (VLPs), and the VLPExpress platform. Plant-based Proficia is a robust vaccine and antibody production system based on transient protein expression in plant leaves. VLPs mimic the native structure of a virus, allowing them to be recognized readily by the immune system without the core genetic material, making them non-infectious and unable to replicate. VLPExpress is a high-throughput platform that accelerates the discovery and development of new vaccines by rapidly expressing, purifying, and testing candidate VLPs. Medicago has reported positive results from its Phase II clinical trial with its avian flu H5 pandemic vaccine candidate. The company has also had positive results from a U.S. Phase I clinical trial with its seasonal influenza vaccine candidate. In July, the biopharmaceutical company announced that it would be acquired by Mitsubishi Tanabe Pharma in a transaction valued at $357 million.