Complex problems sometimes call for practical solutions. As patients languish on waitlists for cell therapy, the industry is looking for new ways to make treatments available sooner and at lower cost. Now, a partnership between a cell engineering platform startup and a modular robotics maker could help ease the bottleneck burden.

Drug delivery specialist Portal Biotechnologies and robotics maker Multiply Labs have teamed up with the goal of creating a “cartridge” for genetic engineering that combines cell-busting technology with automated robotic laboratories.

Portal Biotechnologies, led by former SQZ Biotech CEO and PharmaVoice 100 honoree Armon Sharei, boasts a platform for the “mechanical disruption of cells” to allow cargo such as genetic material into the cell. The precisely engineered silicon filter breaks cells open as they pass through, a technique called mechanoporation. Other methods usually involve viral vectors or electricity, which both have drawbacks.

Despite Portal’s simplification of the cell therapy process, the technology currently requires hands-on work from highly educated workers, presenting financial and time-constraining challenges. And that’s where robotic solutions from Multiply come into play.

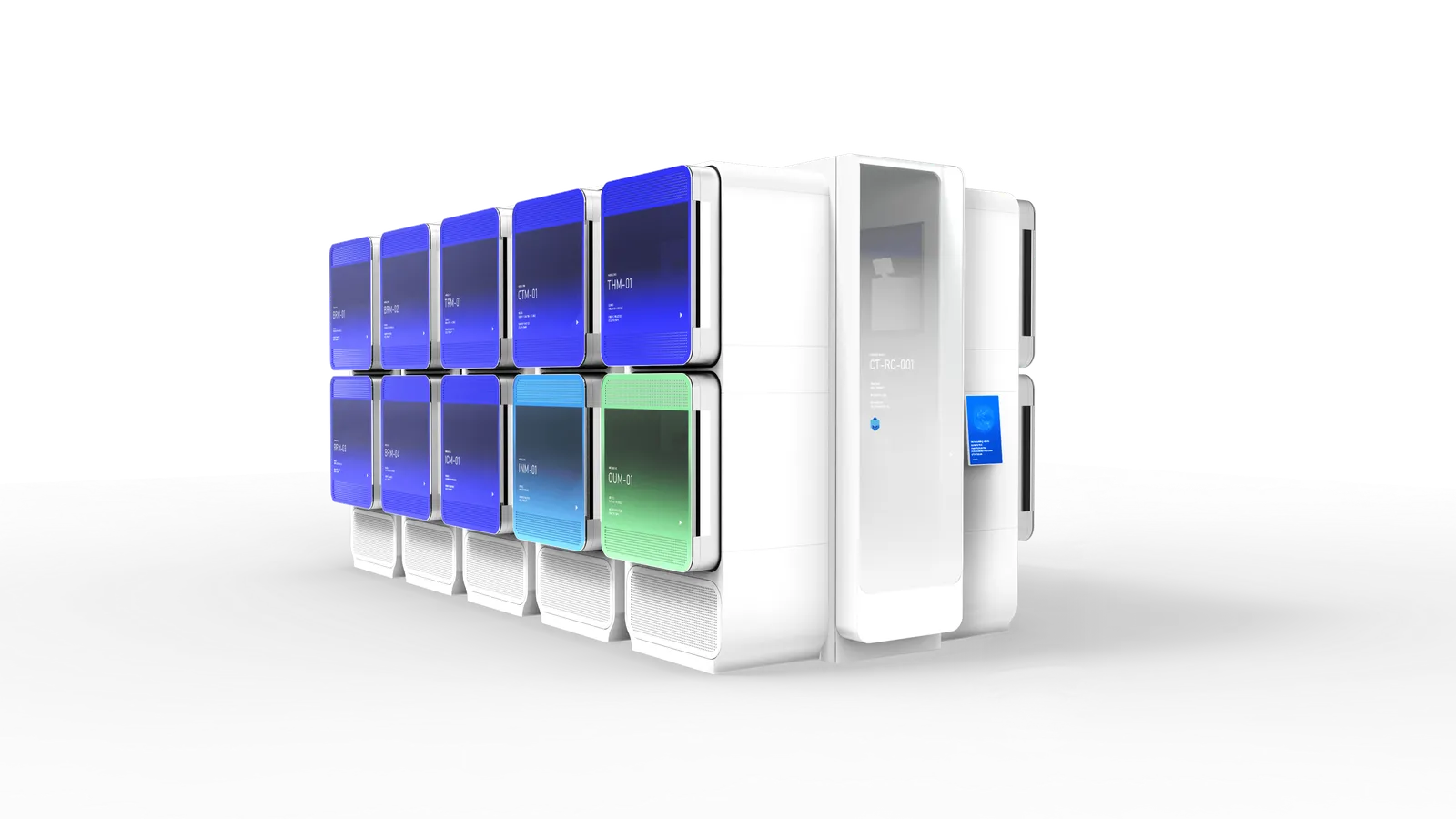

Multiply’s modular robotics system contains the work of 10 laboratories in a box the size of a closet, each with robotic arms that can complete complex tasks precisely. While cell therapy manufacturing requires clean rooms and days of work around the clock, Multiply’s system could cut costs by 70%, CEO Fred Parietti said. As much as 50% of manufacturing cost “is driven by labor costs and limited availability of skilled labor,” according to a study Parietti published in March.

“This is the perfect application for automation — trying to use MDs and PhDs to manufacture at scale is unsustainable,” Parietti said. “With this, you can basically build a sweatshop that’s based on the most expensive and skilled labor you can possibly imagine.”

For Sharei, automation is not just a handy tool but the only way cell therapy can be feasible as manufacturing constraints prevail.

“You’ve got to be able to automate [cell therapy] to have an impact on the cell engineering step itself, but also to simplify the upstream and downstream of manufacturing that cell therapy,” Sharei said.

From bespoke to scalable

To take a patient’s cells and engineer them to fight disease is a complicated process that requires multiple days of cleanroom access with a team of six to 10 operators in shifts, Sharei said. He foresees a new generation of cell therapies coming out of a less workforce-intensive environment.

“By streamlining the process, we can help reduce the footprint dramatically,” Sharei said. “Now that you add this flexibility of programming whatever you want in a scalable way with the work Multiply is doing, that’s how you can amplify the impact of these next-generation therapeutics.”

The cell therapy bottleneck is a surmountable problem, Sharei said, in the same way other new technologies have stumbled out of the gate before taking off. For example, large molecules were difficult to create and administer before the advent of recombinant DNA technology.

“With the invention of recombinant DNA technology, you suddenly had a simple, scalable way to make whatever you wanted, underpinning the massive wave of biologics that have made a huge difference for people,” Sharei said. “Cell therapy is in a similar juncture where it’s so bespoke and complicated to make, and we can make it much simpler.”

From a robotic manufacturing point of view, Parietti sees a future in which once difficult processes can become much less cumbersome.

“You go from technologies that are manually made and crafted to ones that can be made at industrial scale,” Parietti said. “Some people discuss robots doing chores for you — I think it’s much more interesting to apply the same technology to develop and manufacture life-saving therapies.”

A platform approach

Portal and Multiply both operate as platform makers — whether it’s cell engineering or robotics — that can offer their services to companies in need of solutions. Sharei made this Portal’s business model after his experience with SQZ, which he said became too involved in pursuing individual therapies as opposed to helping other biopharma companies pursue theirs. SQZ, which at one point raised over $100 million, sold all its assets earlier this year.

“If you go down the therapeutic path, your fortunes will be very tied to whether that lead therapy does well — if there are hiccups, then it can take the whole platform down with it,” Sharei said. “That’s why we like this platform business model.”

Multiply aligns well with that model, and with both platforms combined into one automated process, they can together offer cell therapy makers a more complete picture of the manufacturing journey.

“Cell therapy developers are comparing manual and robotic processes, and so it’s very cool that now there’s a compelling, non-viral strategy for editing these cells thanks to Portal,” Parietti said. “Once people see the robots are equivalent to the manual process but much more efficient, then they start deploying this in their GMP, and that’s the ultimate goal for us.”

Being a platform player in the biotech and pharmaceutical world can be tricky to navigate, though, as startups like Portal tend to move at a different pace with a different risk structure from their Big Pharma counterparts, Sharei said.

“It’s a little bit of a paradox for them, where on the one hand, they’re very excited about innovation and new things, and they love dealing with fresh grads, but they tend to be very conservative,” said Sharei, whose former company partnered with pharma giant Roche. “It becomes a matter of how flexible you are in your business model because, in the end, they also want to make the world a better place, and they tend to get in their own way.”

Building an ecosystem of partners is a critical step, said Parietti. Multiply works with industry partners like Thermo Fisher and Cytiva, as well as academic institutions like Stanford Medicine and the University of California in San Francisco. And Portal has picked up $5 million in pre-seed venture funding.

Next year, the companies plan to launch a pilot commercial application. And as Multiply and Portal speak to potential clients in the Big Pharma realm, which the CEOs left unnamed for now, the goal moving forward is to keep the research wheels turning to build the kind of credibility it takes to enter that world.