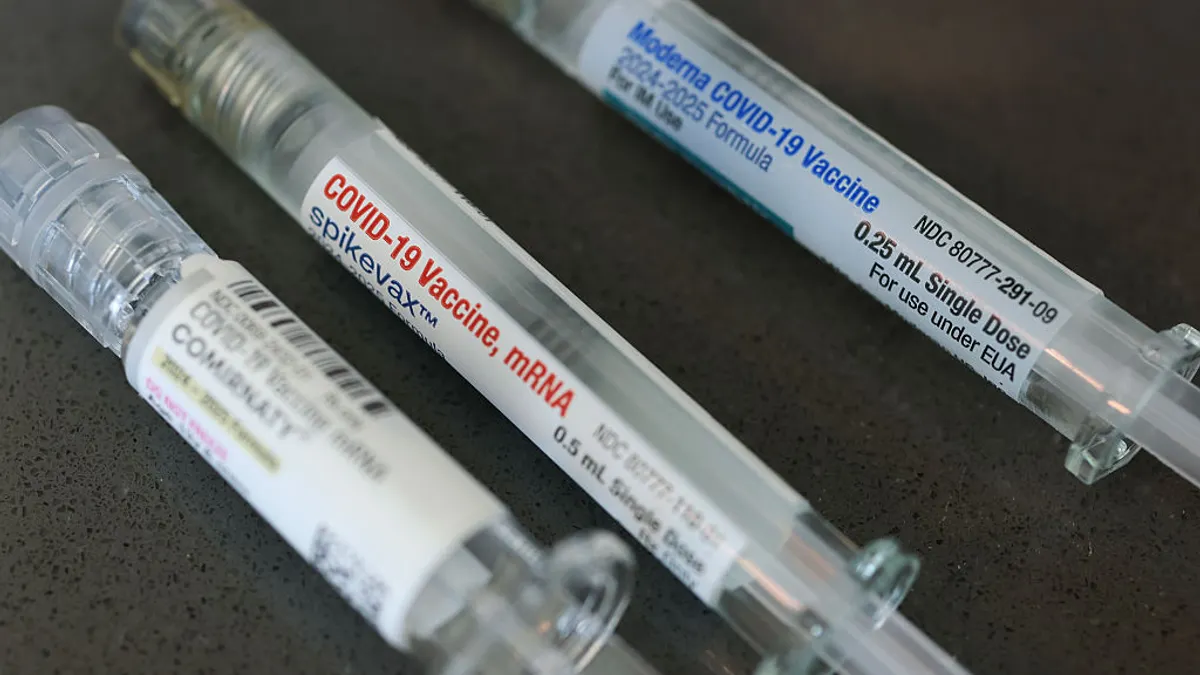

With the major growth of biologics in the last few years — from the rise of mRNA to the biosimilars boom to the insatiable demand for GLP-1s like Ozempic — many containment and delivery manufacturers have been riding a wave of accelerated innovation.

Stevanato Group, the Italian manufacturer that leads the world in production of pre-sterilized vials and insulin pen injectors, has seen the jump firsthand. The company’s revenue grew 17% year over year in 2022 and the number of biopharma clients in its books rose past 700 — with 41 of the top 50 pharma companies and 15 of the top 20 biotech companies among the ranks.

That kind of success doesn’t come without a certain amount of foresight in the biopharma realm, said Riccardo Butta, president of the Americas at Stevanato. By focusing on meeting the needs of the latest biologic R&D, like vial integrity at low temperatures, purity requirements and autoinjector advances, the company has become a key player in the rising sector, Butta said.

Add to that the supply chain issues causing shortages of vials for vaccines, and Stevanato’s market position is an enviable one, delivering the necessary supplies for some of the most in-demand products. The company has an in-house analytical services team to dig further into the needs of mRNA-based vaccines and medicines beyond just supply chain, but adhering to the challenges like cold storage and life cycle management that are particular to that class of molecule.

We spoke to Butta about keeping up with the pace of innovation in the biopharma arena, lasting lessons from the pandemic, navigating ups and downs of a volatile market and client interactions when a drug makes it as big as Ozempic.

This interview has been edited for brevity and style.

PHARMAVOICE: Can you talk about the process of staying on the cutting edge of manufacturing while the biopharma companies you work with innovate at such a fast pace?

RICCARDO BUTTA: What is noticeable compared to a few years ago is that the R&D engines of major pharma and biotech companies is running at a much faster pace. When you look at the pipeline and how rapidly they bring a new product to market, (it) is a big change over the past. From our standpoint, the good thing to start with is a very close relationship with many of them, and so we have good visibility into the pipeline and what they are doing, but we also have a good understanding of the specific requirements they see coming. We engage with customers early on and ask them to characterize the performance of containment solutions and devices to see what can be done to meet those requirements. And when you integrate all these data points, you start to build a picture in terms of where they are going with their needs.

Often we think of biotech and pharma as leading the way in R&D, but how does the manufacturing side influence innovation?

There is a big push and pull on the two sides, and I think we are in a good spot. It’s not only the push on the product side but also with the manufacturing environment. And it’s good to have control of both elements, the process side and the product side because innovation can happen in either of the two.

What lessons did you learn from the quick escalation of the need for mRNA manufacturing and containment during the pandemic?

One lesson we learned was a different way to collaborate with customers and with other people in the industry because to achieve that speed we really needed to change the engagement model and lower the barriers to the end objective. The other one we learned was how to reallocate and reprioritize to move faster. If you look at the speed at which we brought up capacity around vials globally, that was something we couldn’t even think of before. What certain customers did on the pharma side and the drug development side, we did on our end with internal infrastructure, and we mobilized the entire supply chain to do that.

What conversations do you have with companies making GLP-1s, like Novo Nordisk, around capacity?

Every company is different, and the commercial relationship is different as well, but we got a bit of a timing advantage in that specific application, because when you look at our scale-up plans for capacity even before GLP-1 for obesity came around as a major application, we decided to install substantial capacity. We saw the demand for biologics coming and we timed the markets in a very good way. And that is in the conversation with customers to make sure the capacity is going to be there.

What is the current state of the supply chain for products like glass vials and other materials that were difficult to come by?

In general, it’s improving. Of course, there was a bolus of demand and that created extended lead times, but now it’s becoming a more normal, stable situation with better visibility. One area we still see the supply chain still a bit constrained is on the electronic side with certain components for the factory lines, visual inspection lines, optics and the processing that we do there. If you don’t have the components, you cannot produce or you cannot inspect. So that one is still a bit challenging, but not in the way it was last year and two years ago.

How do you navigate the ups and downs of the biopharma markets, particularly post-COVID?

Our portfolio is quite broad and diversified, and so as one component or product or technology goes down, other things have done better. Through those ups and downs, we continue to grow, because ultimately when you look at the market, the market is growing — the fundamental trends are there, and we continue to leverage those.

There is a big push these days around GLP-1 and obesity therapies, for example, and that calls for a lot of capacity around syringes or devices like injectors and pens. So if you look at it today, those are under pressure from a supply chain standpoint, and there is a big effort from us and others to scale up and make sure that capacity is available. And when you look at the pace at which that capacity is being brought online, (it) is quite impressive.